Petrochemicals

Steloy Foundries is recognised as the leading name in the supply of a full range of petrochemical castings, producing custom furnace supports and process tube castings in a variety of heat-resistant alloys for industrial fired and process heaters.

Steloy Foundries is recognised as the leading name in the supply of a full range of petrochemical castings, producing custom furnace supports and process tube castings in a variety of heat-resistant alloys for industrial fired and process heaters.

We supply individual corrosion and heat resistant components as well as complete subassemblies for fired-heater applications covered by API 560 to meet the demands of this challenging industry where safety and quality is of critical importance.

Typical applications include radiant and convection castings for:

Castings for the Petrochemical industry:

Tube Sheets, Brackets & Fittings

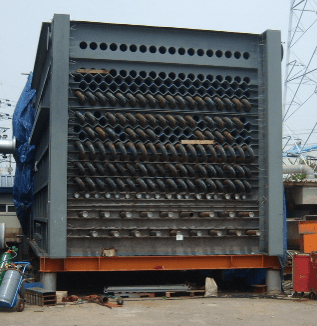

Centrifugally Cast Tubes such as reformer, cracking and catalyst tubes for high-temperature, high-pressure applications are manufactured in accordance with the general requirements of ASTM A608.

Support, Process & Refining Tubes

Produced in accordance with a number of ASTM specifications, static castings can be divided into two main applications: return bends and tube supports.

Gasifier Parts

Steloy Foundries produces every cast component used in the manufacture of the hearth part of gasifier units, the heat resistant stainless steel main grate components.

Fabrication & Testing

Steloy Foundries supplies custom assemblies, including various configurations of heater coils and harps and collectors, using static castings and centrifugally cast tubes.